Leather Weight & Size

Ever grab a piece of leather and think,

“Okay… but how thick is this really?”

What Does Leather Weight Mean?

If someone says “5 oz leather,” they’re talking about thickness, not weight. (No bison on a scale involved.) Leather "weight" is simply how thick a hide is.

Before tools to accurately measure thickness, a one square foot of leather was cut from a hide then weighed.

This gave us the "weight" of the leather.

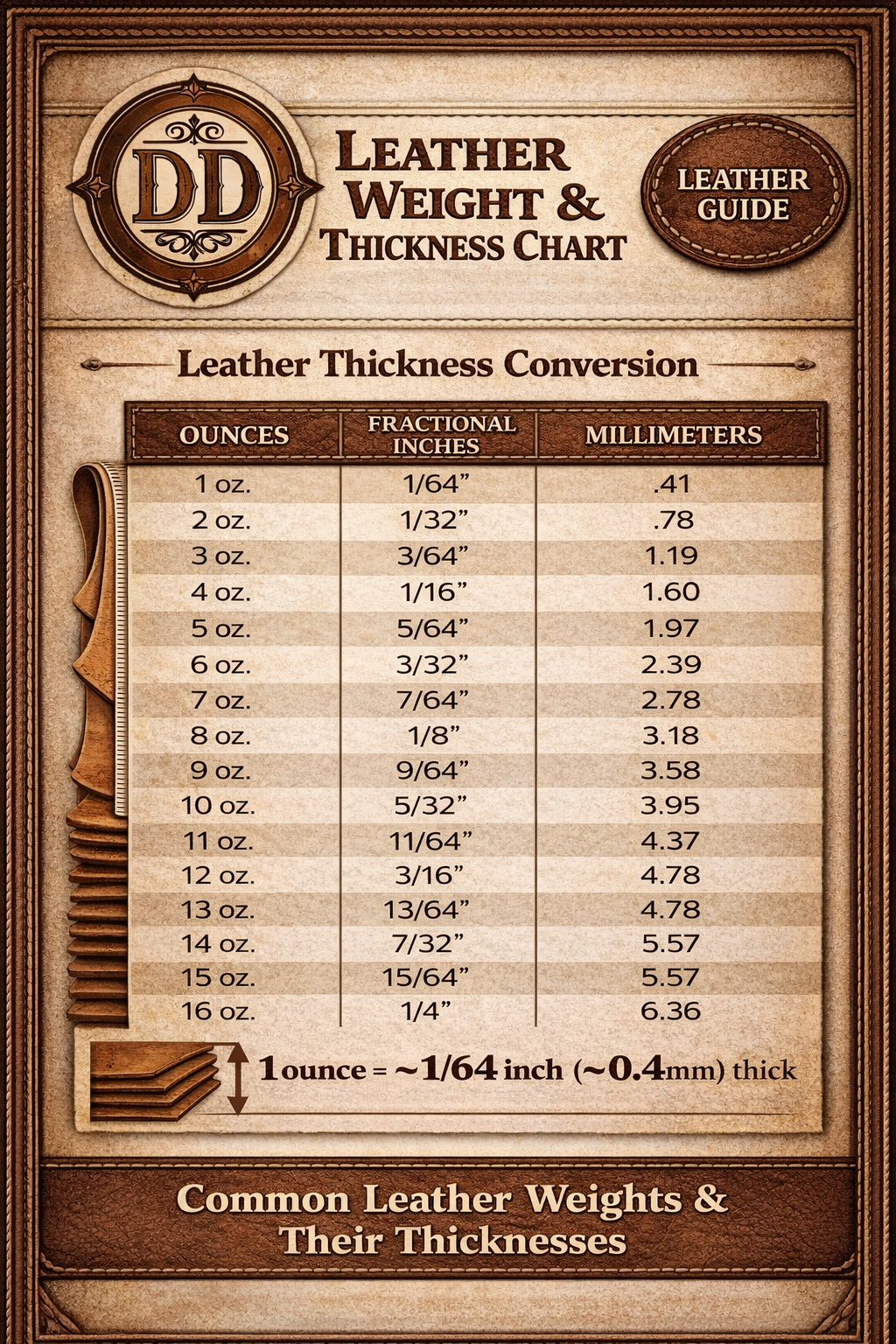

Thickness/weight is measured in:

Ounces (oz) – common in the US

Millimeters (mm) – common everywhere else

Quick rule:

1 oz ≈ 1/64 inch ≈ 0.4 mm

How Leather Thickness Is Measured?

Leathercrafters don’t pinch leather and hope for the best. And we don't need to put a piece on a scale. We use tools.

Leather Thickness Gauges

Clamp-style tools with a dial or digital display. Slide the leather in, close it, read the number. Easy and consistent.

Pro tip: Measure in a few spots—leather will vary throughout the hide.

Leather Thickness Compared to Coins

Don't have a gauge. Most don't. They are pricey. But don't worry... you can use

US coins as a visual reference:

(1) dime is approx. 3 oz.

(1) penny is approx. 3.5 oz.

(1) quarter is approx. 4 oz.

(1) nickel is approx. 4.5 oz.

Trying to figure out something thicker? Just stack your coins.

Not perfect science—but great for quick mental math at the bench and an easy way to try and match a hide you have when ordering more.

Keep in mind that the type of leather (deer, goat, buffalo, etc) does not determine what the leather weight is.

We can process (split) hides to any desired weight/thickness so it is possible to have a buffalo hide that is thinner than a deer hide.

It all depends on the desired weight and end use.

And speaking of splitting...what is it exactly?

A leather splitting machine’s job is to put leather on a very controlled diet—no cheat days.

The hide gets pulled in by rollers, kept flat and steady. Inside, a razor-sharp blade set to a precise height slices through the thickness of the leather. As it moves forward, the blade separates the hide into two layers.

The top layer (the grain side) comes out smooth, strong, and dense, with the natural surface of the leather still intact.

This is the part that looks finished and feels firm and durable.

The bottom layer (the split) comes out softer, fuzzier, and more suede-like, since it’s taken from the inner flesh of the hide.

By the end, you’ve got one piece that’s polished and tough and another that’s soft and velvety.

In short: the machine pulls the leather in, slices it like a very serious deli worker, and sends out two hides with very different personalities.

Since there are a lot of variables we always encourage our customers to reach out with any questions before ordering.

We will gladly help find the right weight leather for your project.

Things to keep in mind

Two hides at the same thickness can feel completely different depending ontannage (veg tan vs chrome tan), finishing process, or temper (soft vs firm)

Thickness tells you how thick the leather is—not how stiff, soft, or flexible it will feel.

Leather is naturally thicker in some areas and thinner in others.

Even when split, small variations are normal.

This is why most hides are labeled as 4-5 oz. or 9-10 oz. due to this variation.

Not sure what the best weight for your project is?

No problem. Just let us know what you're creating and we can make some suggestions.

How Leather Is Measured?

A Buyer’s Guide to Leather Square Footage (Without the Guessing Games)

Leather is not measured like fabric. You can’t just grab a ruler, squint a little, and call it good.

Leather hides are natural, irregular, and shaped very much like… animals.

That’s why the leather industry relies on commercial leather measuring machines to determine accurate size. This guide explains how leather is measured, what square footage actually means, and why math done on the floor usually ends in confusion.

How Commercial Leather Measuring Machines Measure

Leather hides are measured using industrial leather measuring machines built specifically for animal skins.

The hide is laid flat and fed through the machine on a conveyor. As it moves forward, optical sensors or mechanical tracking systems trace the entire outline of the hide, following every curve, dip, and odd-shaped edge nature decided to include.

The machine continuously calculates the surface area as the hide passes through, producing an accurate measurement in square feet—no guessing, no creative geometry.

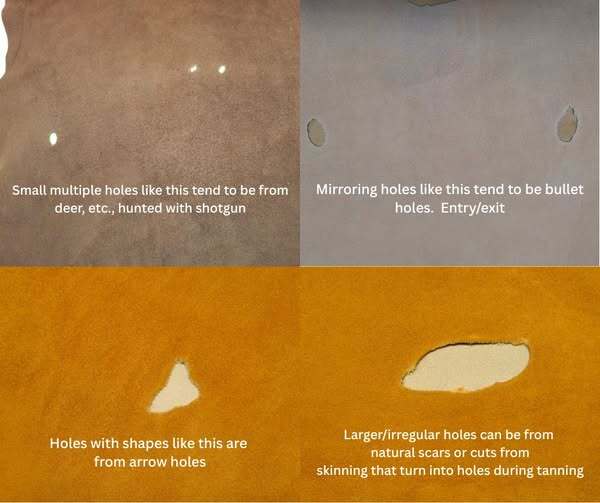

What about the holes?

Leather comes from real animals, so some will have holes.

Commercial leather measuring machines do not count holes or open areas. Sensors detect gaps and automatically subtract them from the total.

You’re paying for leather, not the air where leather used to be.

.

Why Tape Measures and Rulers Don’t Work

Leather hides are:

•Irregular

•Curved

•Asymmetrical

•Absolutely not rectangles

Measuring length by width assumes the hide is shaped like a

sheet of plywood. It is not.

It is shaped like a cow that refused to sit still for geometry class.

Using tape measures almost always leads to incorrect totals

Measuring machines solve this by calculating the true

outline-based area of the hide.

.

So how do I know what the size of my hide is?

Once measured, the size is usually stamped, hand-written on the hide

Most times it's on the reverse side of whatever side the hide was processed for.

Great...but what do the numbers mean?

Leather is measured and sold by the square foot.

It is measured to the nearest 1/4 of a foot.

The first numbers before a dash or dot is the whole footage (in this case 6).

The numbers that follow are the 1/4 foot amount.

6.00 sq ft Written as 6_0

6.25 sq ft Written as 6_1

6.50 sq ft Written ar 6_2

6.75 sq ft Written as 6_3

SQ is short for Square Feet

Things to keep in mind

Two hides can have the same square footage and look completely different.

Long and narrow, short and wide...that’s normal. Leather likes to keep things interesting.

If the dimensions of your project require 4 sf of leather that does not always mean a 4 sf hide will work.

Since they vary in shape and naturally taper form one end to the other, many times you will need a larger hide in order to get your pattern cut.

But no worries...we are here to help. If you're not sure just send us your dimensions and we can find hides the right size and shape for you.